Charles Graves Painting Company

-Class A Contractors License #2705167892 (PTC, RBC and PLB)

-Licensed Master Builder

-Licensed Master Plumber

-Licensed Real Estate Agent, with United Real Estate

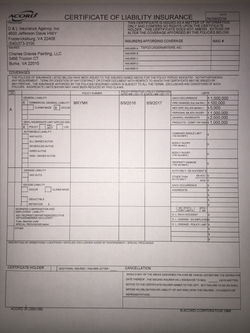

-Insured up to $2,000,000

Nationally and Globally recognized as an industry leader!

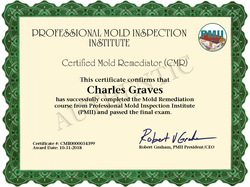

Mold Remediation / Removal / Abatement

We at Charles Graves Painting Company are a fully licensed and insured Northern Virginia mold removal and remediation contractor, licensed painting contractor, and licensed builder, and we are fully certified for both mold remediation and mold inspections. Credentials attached for customer convenience. We happily service Fairfax, Springfield, Annandale, McLean, Great Falls, Arlington, Alexandria, Burke, Woodbridge, Vienna, and all surrounding Northern Virginia cities!

For an in-depth explanation of what mold is, along with how to prevent mold or mildew on exterior (outside) painted surfaces, please see our article, below:

How to Prevent Mold and Mildew on Exterior Painted Surfaces

For an in-depth explanation of what causes mold on the interior of homes, please see our article below: (In short, it involves identifying and fixing the cause of moisture intrusion or leak with a comprehensive mold, waterproofing, and moisture inspection, then remediating the mold and mold spores to get them down to EAL (environmentally acceptable levels).

Causes and solutions for interior mold

To see our full mold remediation process, scroll to bottom of this page.

We offer residential mold inspections for $249 which covers: -Inspection of grounds, exterior, structure, interior, plumbing, crawlspaces, attic, and HVAC-Inspection will be performed in accordance with the Standards of Practice of the National Association of Mold Remediators (NAMRI) and Professional Mold Inspection Institute (PMII)-optional sampling and sending to a lab for an additional charge (labor + lab fee). -Inspection covers both inspecting for visible mold or smell of mold, as well as home conditions which are a risk for water damage/intrusion and mold growth. -All mold inspection customers will be provided a full, multi-page written report documenting findings We offer a 10% discount on any mold remediation services to clients who have hired us for the inspection, and would also like us to remediate. We also will give a $150 discount (down to $99) for the mold inspection, for customers who choose to also hire us for the remediation. Payment Policy: $249 payment is owed at time of booking, to book the inspection. If inspection is canceled by customer, they will be refunded, except for the amount retained due to cancellation policy. If customer reschedules, we will keep payment and reschedule inspection to a new date of customer's choice. Cancellation policy for inspections: Cancellations after inspection booking incur a $125 fee if cancelling after customer's initial phone agreement to book for a specific day/time. Booking is official starting at the time customer gives their verbal, texted, or emailed agreement to the inspection, the date and time of inspection, and provides their name and address.

|  |  |  |  |  |

|---|---|---|---|---|---|

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |

Our mold remediation process meets NIOSH, OSHA, and IAQA standards, and is as follows:

Prior to sending you a proposal/contract or doing the process, we do a FULL INSPECTION to inspect the interior and exterior of home, including grounds, attic, foundation, gutters, inside walls, surfaces, etc for moisture issues that may cause mold or microbial growth in the future. If any are discovered, we will assess the scope of mold remediation needed to eliminate the mold. We will determine whether it is a condition I, condition II or condition III. It is important that all moisture problems be identified and eliminated prior to or during the remediation process.

The remediation process can vary in whether or not we use a biocide, (although we usually do, with few notable exceptions), and a few other minor ways, but generally our process is as follows:

1) Completely turn of all A/C units, and plastic off all vents, and the return system. Create a double-entry zipper containment chamber for entry into mold contaminated area, and seal off the mold remediation area completely with 6mm plastic sheeting.

2) create negative air pressure through the use of an industrial fan and ventilation system bringing air out of the building. This is necessary to prevent mold spores from getting into the vent system or redistributed throughout the building.

3) As the process is going on, we will be using a HEPA VACUUM (throughout), DEHUMIDIFIERS, and AIR SCRUBBERS (throughout). Our company currently owns 3 Force Air 2000 high volume air scrubbers, 3 Vantage commercial-grade 1500 dehumidifiers, 4 Dri-Eaz commercial-grade compact dehumidifiers, and all of the other equipment necessary to professionally complete your mold remediation project safely, completely, and efficiently. The air scrubbers clean the air, trapping mold spores. The HEPA air purifiers further help eliminate any mold spores at the end of the project. The HEPA vacuum allows our crew to vacuum up mold spores, and other materials, without blowing dirty air out. (The HEPA vacuum blows out cleaned filtered air, and doesn't allow mold spores to exit the vacuum. HEPA vacuums are specially made to target contaminants between 1 and 5 microns, which includes mold. NIOSH recommends HEPA filters and air scrubbers during the mold remediation process.).

4) The next thing that we need to do is spray down all mold-infected surfaces, immediately prior to removal. (When mold is wet, it cannot spread its spores through the air.)

5) Then, tear out all old drywall, and all old insulation, all old carpeting, padding and tack strips, and any other mold-infected porous items or surfaces, double-bag in sealed bags, and dispose of it outside. We take the bags outside through the nearest exit to avoid potential spores exiting the bags and contaminating other parts of the home. If it is a basement, we take out a basement door or window. If it is an upstairs bedroom, we take bag through window, unless it is not feasible to do so.

6) Examine the wood framing. Any rotten or moldy wood should be replaced. For moldy framing that cannot be replaced without incurring significant cost (such as load-bearing framing), it should be scrubbed and cleaned with a biocide/moldicide/mildewcide, then encapsulated. Compromised joists that have been damaged from mold enough to hinder their load-bearing capacity must be doubled-up or reinforced to ensure the structural integrity of that joist.

7) Cleaning all hard, nonporous surfaces with an EPA-approved biocide or antimicrobial, if necessary (sometimes bleach and water, but never a mixture of bleach and ammonia). Sometimes, water may need to be removed from cinderblock or brick with a wetvac, depending on the site conditions.

8) During this entire process, dehumidifiers and air scrubbers will be cleaning and eliminating any excess moisture. We will do a surface check before proceeding to step 9.

9) Encapsulate all of the framing and wood in the infected area, to prevent future mold growth and to encapsulate against future moisture penetration.

10) Then, we install new drywall (and cornerpieces), tape the drywall, apply 3 layers of joint compound, then sand, prime and paint 2 full coats. We use a moldicide additive in the new paint, also, to help prevent against mold growth in the future. That way, any few and far between spores, or new spores in the future, would not be able to take hold of those surfaces.

11) Vent cleaning is very important part of mold remediation. Vent cleaning should be done both prior to and after mold remediation.

Mold remediation technology continues to evolve and improve, and research continues to be conducted, so these steps may be updated in future. However, no amendments to existing contracts will be made without customer written approval. These steps are subject to variance, and are not to take the place of a written contract. Every specific job has its own site conditions.